Blocks water penetration through coatings (e.g., polyurethane) or membranes (e.g., Gore-Tex®), with hydrostatic head ratings up to 20,000 mm, ensuring dryness in heavy rain or snow.

Seam-sealed construction prevents leaks at stitching points, critical for extreme environments.

Microporous membranes (e.g., Gore-Tex, eVent) allow sweat vapor to escape while blocking liquid water, maintaining thermal balance during high exertion.

Technologies like c_change adapt to body temperature, opening pores during activity and closing them in cold conditions.

Windproof properties due to tightly woven or laminated structures, reducing wind chill.

UV-resistant coatings (e.g., TPU fabrics) protect against sun damage.

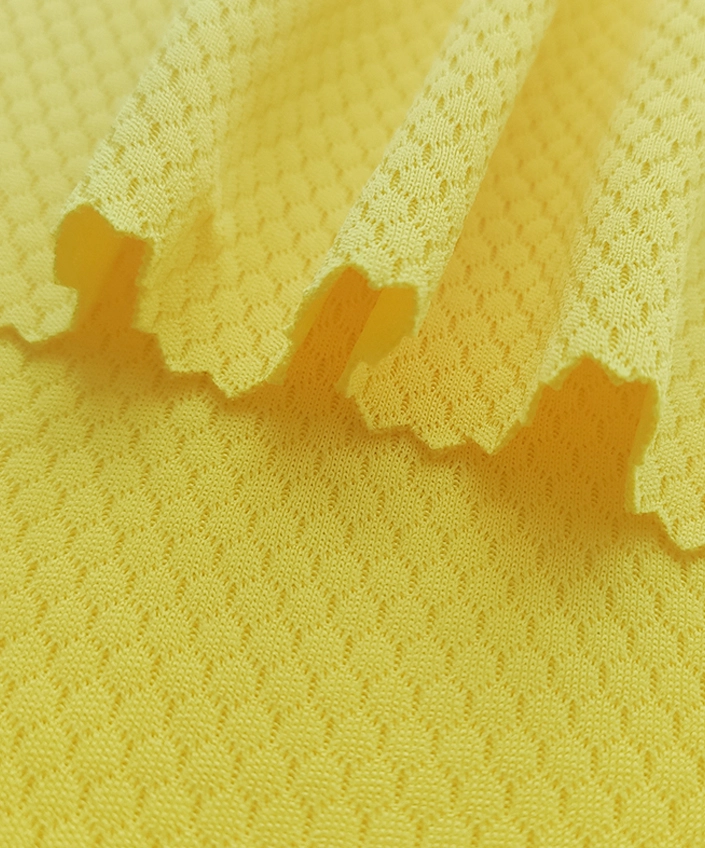

High-denier nylon or polyester fabrics resist abrasion and tearing, ideal for rugged outdoor use.

Lightweight laminates (e.g., 2.5-layer Gore-Tex) reduce bulk without compromising performance.

Softshell fabrics with stretch properties (e.g., Storm Cotton) combine mobility with urban-friendly designs.

Luxury adaptations (e.g., Loro Piana’s Storm System) integrate waterproofing into wool or cashmere for refined outerwear.

Recyclable materials like TPU replace PVC to reduce environmental impact.

Bio-based membranes (e.g., eVent BIO) align with eco-conscious manufacturing trends.

Meets international standards (e.g., ISO 810, AATCC 100) for waterproofness and breathability, ensuring reliability.

Microporous Membranes:

Gore-Tex®: Uses PTFE membranes with 0.1–5 μm pores to block liquid water while allowing vapor escape (>10,000 g/m²/24h breathability).

eVent®: Features direct-venting technology for faster moisture expulsion (5,300 g/m²/24h breathability), ideal for high-intensity activities.

Polyurethane (PU) Coatings: Cost-effective and lightweight, modern variants like Aquatex® enhance flexibility and abrasion resistance.

Hydrophilic Solid Films:

Sympatex®: A polyester-based film that transports vapor via molecular diffusion, excelling in humid environments (hydrostatic head >20,000 mm).

Synthetic Blends: High-density nylon/polyester laminates (200–600gsm) offer tear resistance and UV protection, suitable for extreme conditions.

Natural-Synthetic Hybrids:

Waxed Cotton: Treated with paraffin/beeswax for vintage-style waterproofing.

Bamboo-PU Blends: Combine antimicrobial properties with eco-friendly coatings.

Recycled Materials:

Ocean Recycled Nylon: Reduces CO2 emissions by 91% compared to traditional nylon (e.g., DEEPBLU’s triple ripstop fabric).

Fluorine-Free Treatments:

Maxtrytex Mavis: Utilizes eco-friendly coatings without harmful fluorides, ensuring safety for sensitive users.

Bio-Based Membranes: eVent BIO uses plant-derived materials (e.g., castor beans) to lower carbon footprints.

Circular Practices: Recycled TPU replaces PVC in coatings, aligning with global sustainability standards.

Pre-Treatment: Clean fabrics with pH-neutral detergents to ensure optimal coating adhesion.

Layering Techniques:

3-Layer Construction: Combines outer fabric, membrane, and inner lining for durability (e.g., Gore-Tex Pro®).

2.5-Layer Designs: Reduces weight by bonding a half-layer lining (e.g., Gore-Tex Paclite®).

Seam Sealing: Critical for preventing leaks in extreme environments.

Waterproof Standards: ISO 810 (hydrostatic pressure >20,000 mm).

Environmental Compliance: Bluesign® or OEKO-TEX® ensures chemical safety and low-carbon production.

Nikwax TX.Direct® Spray: Restores DWR (Durable Water Repellency) without heat, extending garment lifespan.

Wash Care: Use mild detergents and avoid fabric softeners to preserve waterproof coatings.

Triboelectric Nanogenerators (TENG): Waterproof fabrics integrated with energy-harvesting tech for self-powered sensors (e.g., WPF-MTENG).

Graphene-Enhanced Textiles: Improve thermal regulation and antibacterial properties while maintaining waterproofness.