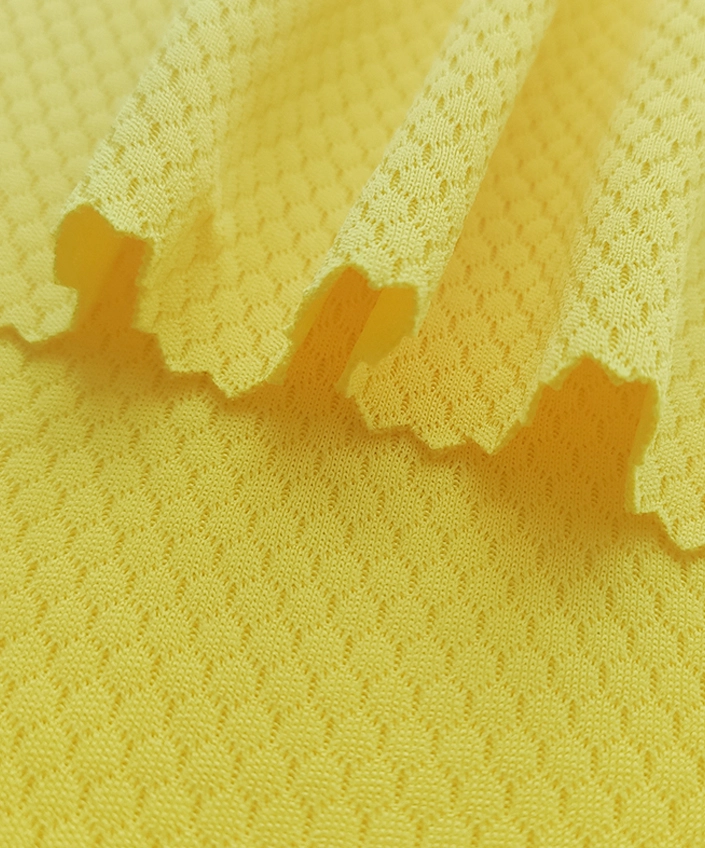

Dry Fit is a high-performance synthetic fabric engineered for rapid moisture-wicking and quick-drying, primarily used in sportswear and outdoor apparel. Composed of polyester or nylon blended with spandex, its hydrophobic fibers create capillary action to pull sweat away from the skin, accelerating evaporation. Innovations like Nike’s Dri-FIT technology utilize microporous structures for breathability and lightweight comfort, ideal for running, yoga, or cycling. Unlike cotton, Dry Fit minimizes chafing, retains shape during intense activity, and often integrates UV resistance or antimicrobial treatments. Brands like Columbia and The North Face enhance it with coatings (e.g., Omni-Tech) for weatherproof versatility

Quick-drying fabrics often incorporate microscopic pores or grooves in fibers (e.g., polyester or nylon blends) to create capillary action. These pores, smaller than water droplets but larger than water vapor molecules, allow sweat to spread across the fabric’s surface and evaporate rapidly . For example, GORE-TEX-like membranes use this principle to balance waterproofing and breathability .

Hollow or Grooved Fibers: Fibers with cross-shaped, Y-shaped, or hexagonal cross-sectionsincrease surface area, accelerating moisture transport. Brands like Coolmax (INVISTA) and Aerocool(Hyosung) use such designs to enhance wicking .

Micro-Groove Technology: Fibers with surface grooves (e.g., Coolnylon) direct sweat outward via capillary channels, reducing drying time .

Fabrics combine hydrophilic (water-attracting)inner layers andhydrophobic (water-repelling)outer layers. The inner layer absorbs sweat, while the outer layer disperses it for quick evaporation. SUNGOD’s Inner Dry Technology exemplifies this, preventing reverse moisture penetration even when external water contacts the fabric .

Shape-Memory Polymers: These polymers adapt to environmental humidity, opening pores when moisture levels rise to boost breathability .

Nanotechnology: Microporous coatings (e.g., nano-SiO₂) enhance moisture transfer. For instance, Anta’s "Speed King" T-shirts use microporous polyester fibers developed by Sinopec’s Yizheng Chemical Fiber .

Microwave-Convection (MWC) Drying: Effective for removing free water from fabrics, MWC ensures uniform drying with minimal shrinkage, outperforming traditional hot-air methods .

Heat-Pump Dryers: Optimize energy efficiency by balancing drum rotation speed and airflow, preserving fabric integrity .

Recycled Materials: Brands like New Balance use100% recycled polyester in quick-drying apparel, reducing environmental impact .

Biodegradable Fibers: Innovations like PBAT/PVA composite fibers(Anta) combine quick-drying properties with biodegradability .

For example, Nike’s Dri-FIT technology uses a microporous structureto pull moisture to the fabric’s surface, outperforming traditional cotton, which retains moisture and causes discomfort. This feature is critical for sports like running and yoga, where prolonged dryness enhances performance

The fabric’slightweight and breathable construction allows unrestricted airflow, reducing heat buildup. Brands like Adidas and Under Armour integrate hybrid blends (e.g., 88% polyester + 12% spandex) to balance elasticity and ventilation. Military-grade applications, such as the U.S. Air Force’s updated PT uniforms, utilize Dry Fit-inspired materials with antibacterial treatments to prevent odor during extended wear

Dry Fit fabrics resist wear, pilling, and UV degradation, even after repeated washes. Innovations like TPU coatingsor hybrid weaves (e.g., polyester-spandex blends) enhance durability for outdoor activities, while maintaining flexibility. For instance, Feimei Knitting’s Zurich Dry Fit (250GSM) is engineered for high-intensity training and retains shape under stress.

Brands leverage digital jacquard looms and heat-transfer vinyl (HTV) to imprint intricate designs without compromising fabric integrity. The integration of smart textiles, such as conductive threads for motion tracking, aligns with trends in wearable tech. Future advancements may include biodegradable Dry Fit variants, like Anta’s PBAT/PVA fibers, to meet sustainability demands

Global demand for performance wear drives brands to adopt Dry Fit as a competitive differentiator. Israeli manufacturer Polaris prioritizes Dry Fit for military gear due to its moisture-wicking reliability, while retailers like New Balance emphasize recycled polyesterversions to appeal to eco-conscious consumers