As a vertically integrated textile manufacturer, we specialize in producing high-performance fabrics through a streamlined 9-step process:

Yarn Texturizing: Textured yarns are processed via advanced texturizing machines to enhance elasticity and durability.

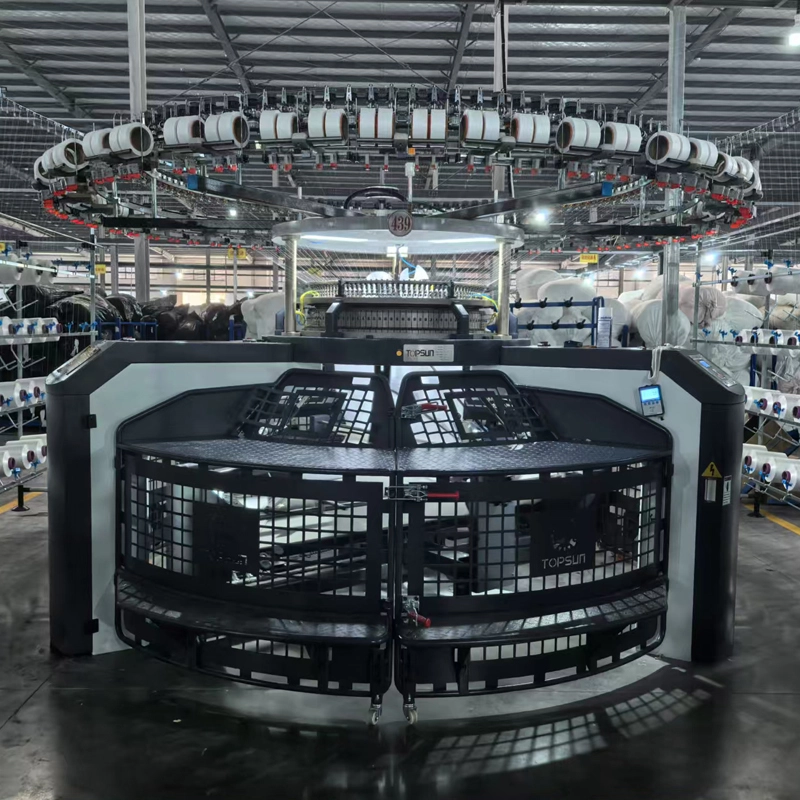

Circular Weft Knitting: 400+ circular knitting machines weave yarns into greige fabric with precision, ensuring uniform texture.

Greige Fabric Storage: Fabric is stored in climate-controlled warehouses (40,000㎡ capacity) to maintain quality before dyeing.

Lab Color Matching: Customized dye formulas are developed using spectrophotometers to meet client-specific Pantone standards.

Dyeing Vat Process: 12 dyeing lines achieve ≤0.8% color deviation with OEKO-TEX certified chemicals for eco-compliance.

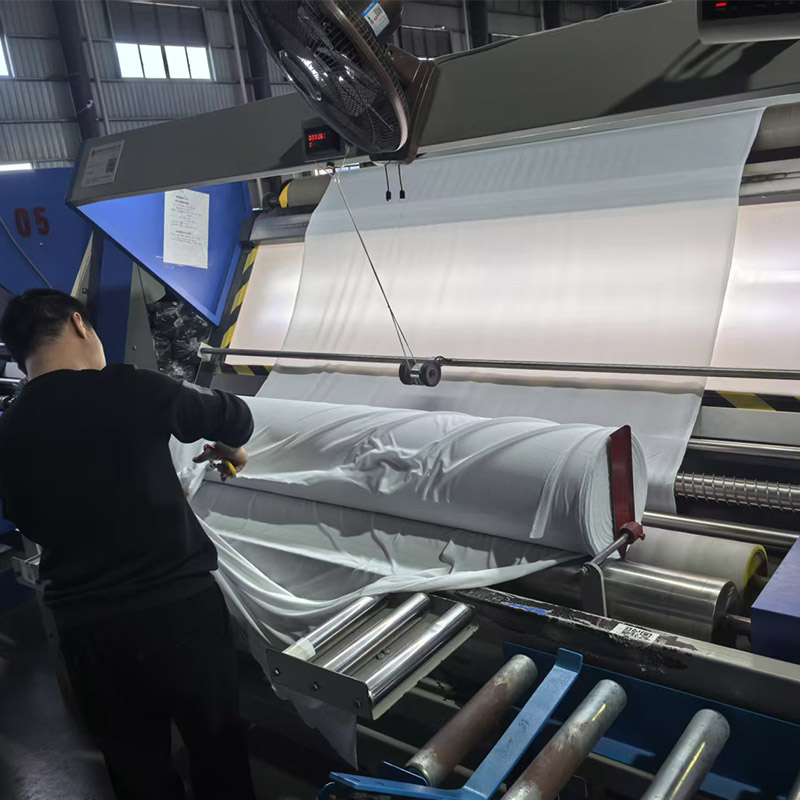

High-Stability Setting: Stabilize fabric dimensions and enhance functional properties (e.g., UV resistance) through controlled heat.

Final Inspection: Automated sensors and visual checks detect defects (e.g., pilling, color shifts) to ensure 99.98% compliance.

Auto Packing: Robotic systems package finished fabrics with barcode labeling for traceability and rapid logistics.

Warehouse & Dispatch: GRS-certified成品仓 integrates ERP for real-time inventory tracking and global shipment preparation.

Certifications: GRS, ISO 9001, OEKO-TEX. Markets: Asia, North America. Strength: End-to-end control from yarn to shipment, 72-hour rapid prototyping.