Because it’s one of the most produced and consumed synthetic fabrics in the world, polyester is readily available in a wide variety of styles, weights, and finishes. Whether it’s smooth, textured, or mesh, polyester can be produced in many forms to suit different needs.

Polyester is incredibly strong and resistant to stretching, shrinking, and abrasions, which makes it highly durable.

It repels water, which is one of the reasons it is favored for activewear and sportswear. It helps keep you dry by wicking sweat away from the skin and dries faster than most other fabrics.

Low Maintenance: It resists wrinkles, fading, and shrinking, so clothes made from polyester require less ironing and maintenance. Because it dries quickly, it's also mildew-resistant to a certain exten.

Why Polyester Fabric is Cost-Effective

Polyester’s cost-efficiency stems from petrochemical-derived raw materials (PTA/MEG) with stable pricing, high-volume production efficiency (1 ton of polyester yarn costs ~15% less than nylon.), and recyclability (Existing PET bottle recycling streams cut sourcing costs by ~20%.). Its durability lowers garment replacement rates, while easy blending (e.g., with spandex) enhances functionality without major cost hikes.

Polyester can be blended with other fibers like cotton, wool, or elastane, giving it a range of properties depending on the intended use to create hybrid materials with the best features of each fiber.

Virgin PET chips or recycled flakes (e.g., REPREVE® from plastic bottles) are purified and dried (≤50ppm moisture) to ensure melt-spinning stability.

PET melted at 290-300°C is extruded through spinnerets, cooled into filaments, then drawn 3-5x to align polymer chains for strength (4-6g/denier).

Filaments pass through high-speed air jets or false-twist machines to create crimped texture, enhancing elasticity (common for sportswear yarns).

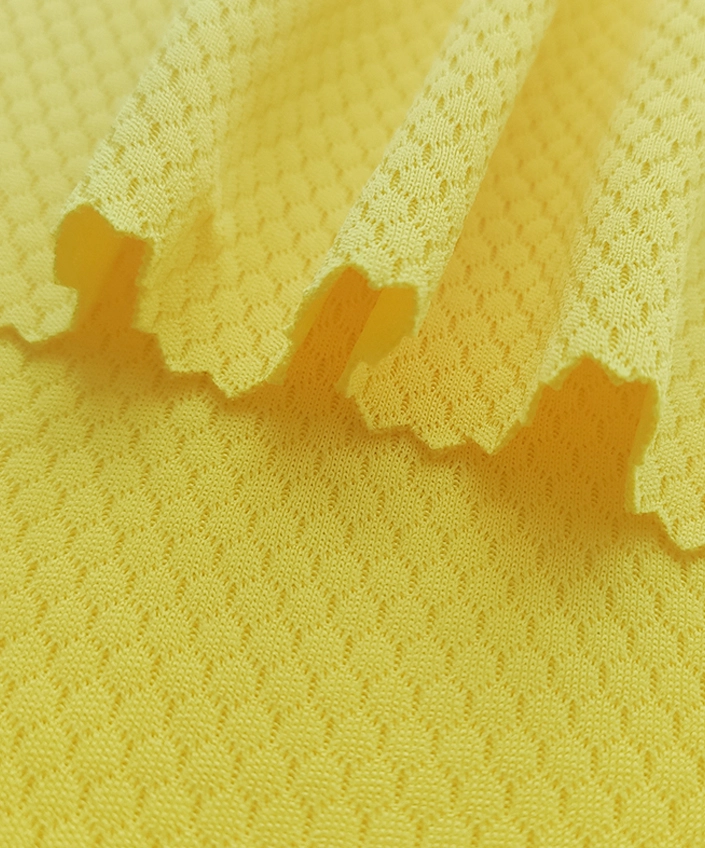

Yarns are woven (plain/dobby) or knitted (single jersey/pique) on 32-inch circular machines (400+ units mentioned) for breathability/stretch.

Jet dyeing with disperse dyes (130°C for colorfastness), followed by anti-pilling/UV-resistant coatings (OEKO-TEX certified chemicals).

Post-consumer waste is shredded → depolymerized into BHET → re-polymerized (closed-loop for GRS certification).

Vertical control from recycled flakes to finished fabric (72-hour lead time);

12 dyeing lines with ≤0.8% color deviation (ISO 9001);

Custom functional finishes (e.g., moisture-wicking, chlorine resistance) tailored to sportswear brands.